Automotive Applications

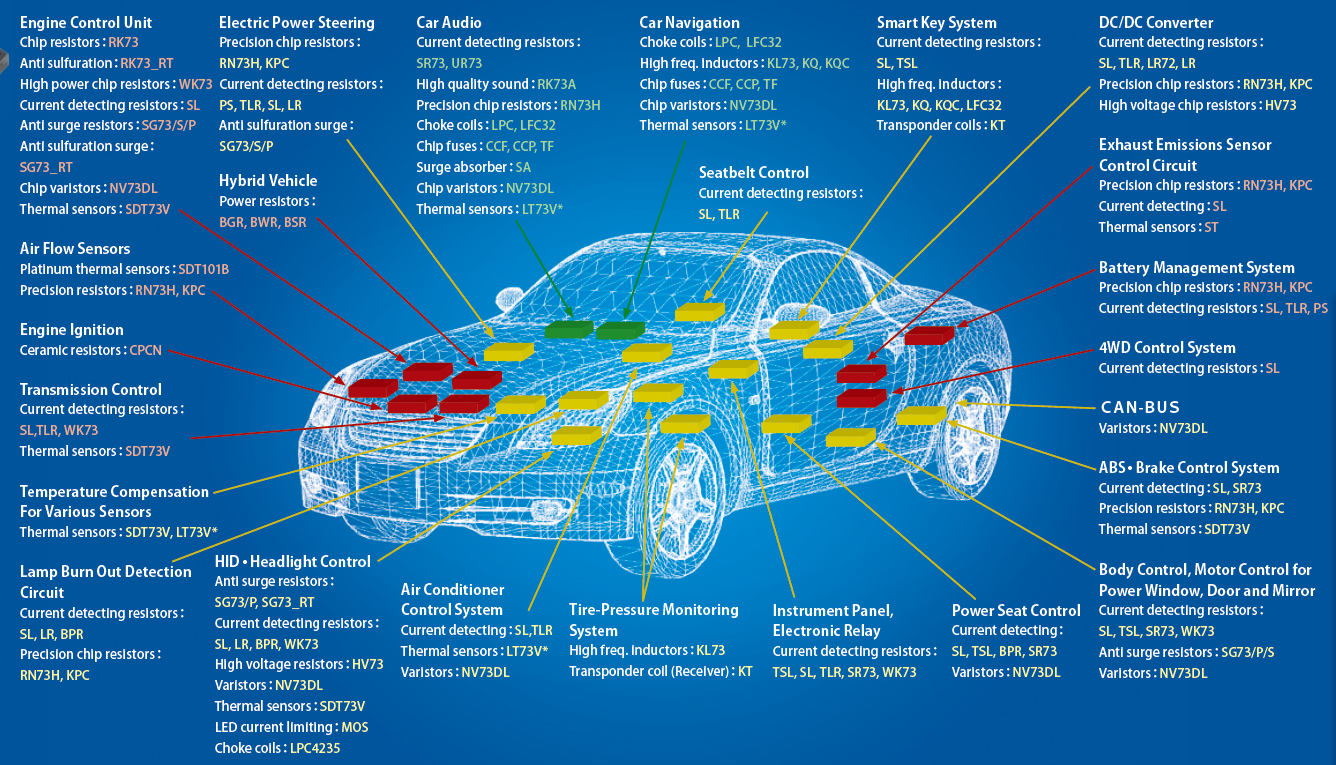

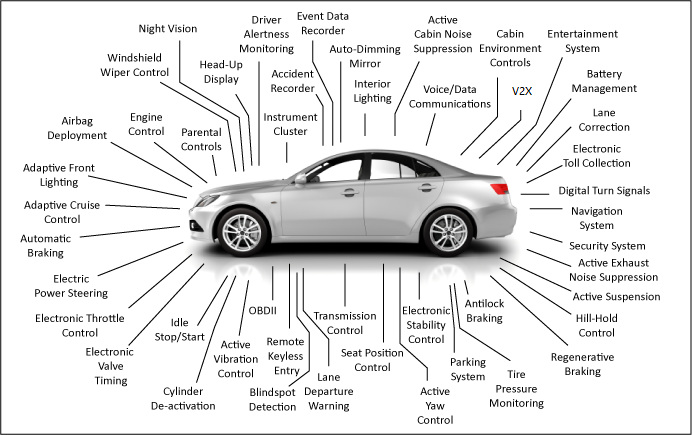

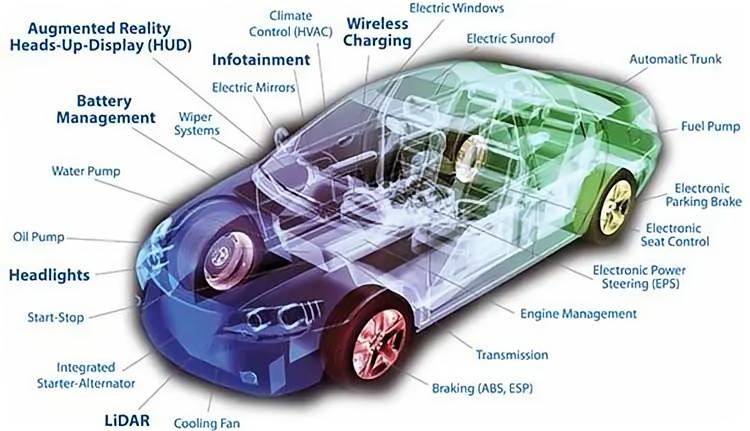

In the automotive domain, chips are the linchpins of modern vehicle functionality. Engine Control Units (ECUs) rely on microcontrollers to manage engine performance. These chips precisely regulate fuel injection, ignition timing, and air – fuel mixture, optimizing fuel efficiency and reducing emissions. For example, a high – performance microcontroller can process real – time sensor data from the engine, such as temperature, pressure, and oxygen levels, and adjust engine parameters accordingly within milliseconds.

In safety – critical systems like Anti – lock Braking Systems (ABS) and Electronic Stability Control (ESC), specialized chips ensure rapid response times. They receive data from wheel speed sensors, yaw rate sensors, and lateral acceleration sensors. Based on this data, the chips calculate the appropriate braking force for each wheel, preventing wheel lock – up during hard braking and maintaining vehicle stability in challenging driving conditions.

The infotainment systems in cars also heavily depend on chips. Multimedia processors handle tasks such as playing high – definition videos, running navigation software, and connecting to mobile devices via Bluetooth or Wi – Fi. These chips need to have sufficient processing power to support smooth user interfaces and multitasking, providing drivers and passengers with an enjoyable and connected driving experience.

Integrated Silicon Solution Inc. (ISSI) in Automotive

ISSI has been an integral part of the automotive market since 1999. In 2001, it established the Automotive Business Unit to further its support. This unit offers cross-functional support within ISSI, enhancing automotive infrastructure from product planning to production, leveraging its SRAM, DRAM, and Flash product families.

ISSI addresses a major concern of automotive customers – long – term product support. Given the 3 – 4 – year design cycle from inception to production in the automotive market, followed by 5 – 6 years of production and several more years of post – production support needs, ISSI commits to providing sustained support. It works with customers on three temperature – graded automotive products: -40°C to +85°C, -40°C to +105°C, and -40°C to +125°C. Products are designed and fully tested to function within these temperature ranges.

ISSI’s quality management is top – notch. With ISO9001:2000 certification and all subcontractors in the automotive production flow being ISO/TS 16949 certified, new products meet or exceed AEC – Q100 qualification standards. The company’s comprehensive quality system, with all production phases controlled and documented in standard automotive PPAPs, ensures the highest quality.

In terms of product offerings, ISSI provides a wide range of memory solutions for automotive applications. For example, it has a complete portfolio of high – performance SPI Flash products, with voltage support for 1.8V and 3V, which are increasingly used in ADAS applications and other growing segments of the automotive market. ISSI also introduced AEC – Q100 qualified SLC NAND Flash for automotive and industrial markets. Additionally, it offers a variety of LPddr4 & LPddr4X products from 2Gb through 32Gb, as well as LPddr2 in densities ranging from 256Mb to 8Gb, catering to different in – vehicle requirements.

Texas Instruments (TI) in Automotive

TI has been driving automotive innovation forward. Its growing portfolio of analog and embedded processing products is based on decades of automotive expertise, enabling continuous innovation. TI offers comprehensive and reliable products, designed with cost – effectiveness and high performance in mind.

Product longevity and assurance of supply are key aspects of TI’s automotive offerings. The company invests in manufacturing capacity to meet product demand for decades. This ensures that automotive manufacturers can rely on a stable supply of TI chips for their long – term production needs.

TI helps automotive designers accelerate the design process. From functional safety to innovation requirements, TI provides design, quality, reliability, packaging, and PPAP tools. These tools assist in streamlining the journey from concept to design and finally to production. For instance, designers can efficiently achieve ISO 26262 safety system certification by using TI’s functional safety – compliant analog and embedded processing products, documentation, and resources. TI products adhere to accredited development processes, helping to achieve the highest automotive safety integrity level (ASIL) and safety integrity level (SIL) required by the design.

TI also simplifies the supply chain with its high – quality and reliable semiconductors and documentation. The data download tool provides easy access to environmental, reliability, and packaging information, from RoHS to material content to fit estimates.

In automotive applications, TI offers diverse products. Its DLP® technology is used in automotive interior and exterior display and lighting applications. The DLP automotive product family has a scalable platform that operates consistently within – 40°C to 105°C, meeting various brightness and resolution requirements. For example, small exterior vehicle lights designed with DLP® technology can project vehicle information, pedestrian warnings, and style features in full – color video and images in a 360 – degree manner. In addition, TI’s products are used in automotive camera systems, where its high – efficiency processing and communication technologies enhance vehicle vision by transmitting high – resolution, uncompressed camera data and processing it in real – time.